User Tools

Sidebar

This is an old revision of the document!

Table of Contents

SPECFEM3D

Tutorials

Tutorial 1: Homogeneous halfspace

The following instructions assume that you have installed SPECFEM3D and familiarized yourself with how you will run the package based on your computer configuration, as detailed in the SPECFEM3D User manual (Chapter 2 provides installation help). Additionally, we will make use of an external, hexahedral mesher CUBIT. Please make sure you have these packages installed on your system.

The example is distributed with the package under the examples/ directory. However, you might need to edit these example scripts slightly to launch them on your system.

Homogeneous halfspace

This is a step-by-step tutorial how to create a mesh for a homogeneous halfspace, export it into a SPECFEM3D file format and run the mesh partitioning and database generation.

Meshing

In the following, we will run a python script within CUBIT to create the needed mesh files for the partitioner.

1. change your working directory to the example folder:

[]$ cd SPECFEM3D/examples/homogeneous_halfspace

2. start the graphical user interface (GUI) of CUBIT:

[homogeneous_halfspace]$ claro

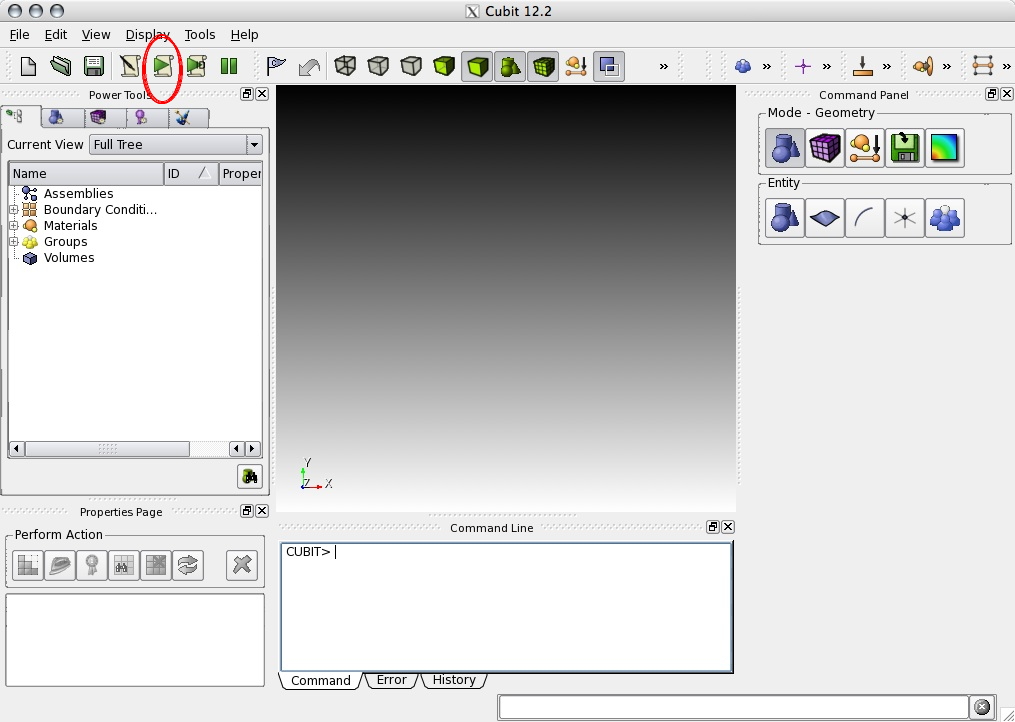

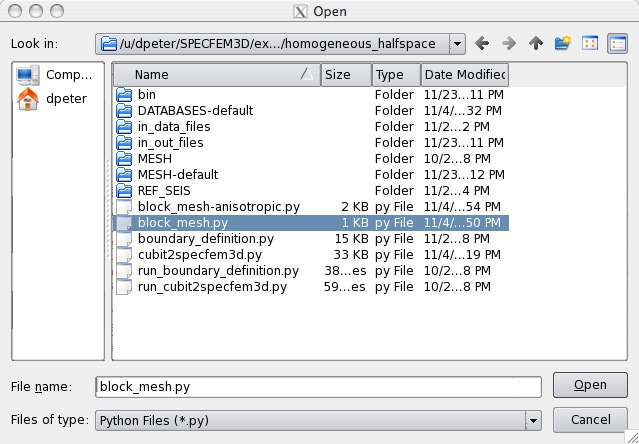

3. run the python file “block_mesh.py”:

use the (Play Journal File) button and open the file 'block_mesh.py'

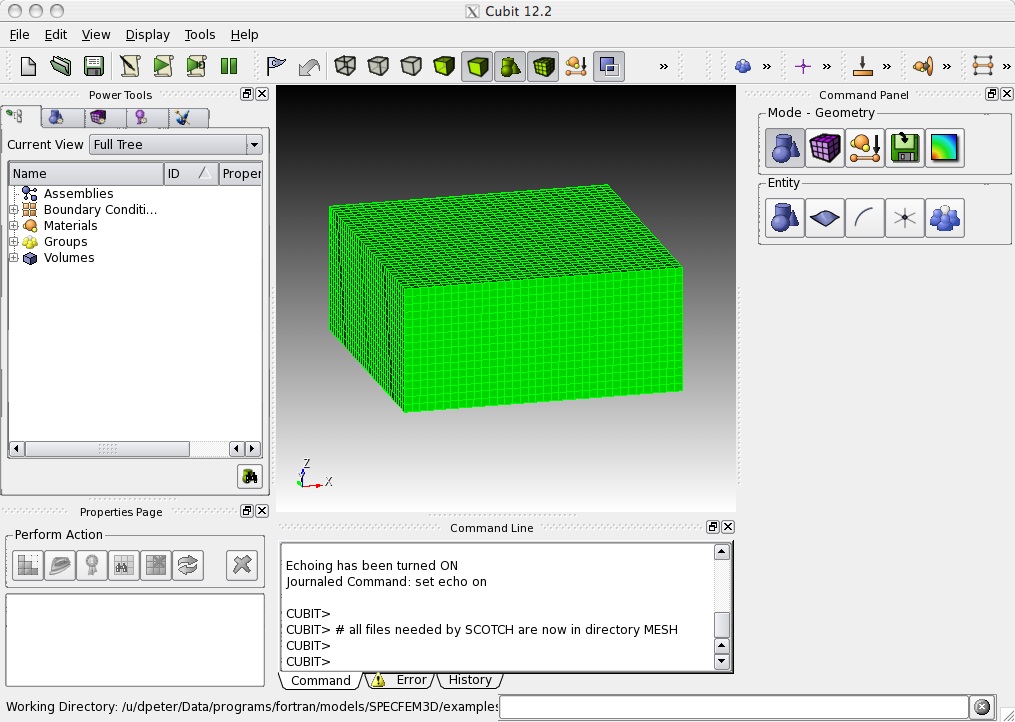

4. in case the script executed successfully, it should create you a single volume with a regular mesh

check that the script created a new folder “MESH/” containing the files:

[homogeneous_halfspace]$ ls -1 MESH/ absorbing_surface_file_bottom absorbing_surface_file_xmax absorbing_surface_file_xmin absorbing_surface_file_ymax absorbing_surface_file_ymin free_surface_file materials_file mesh_file nodes_coords_file nummaterial_velocity_file

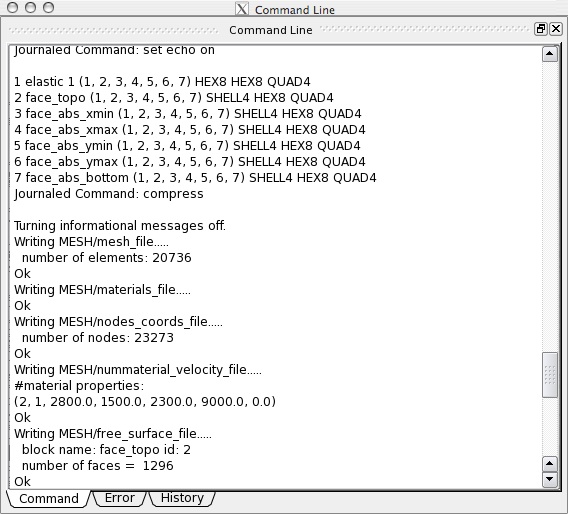

you can also check if the export was successful by examining the output in the Command line window of CUBIT. The sensitive part should look like

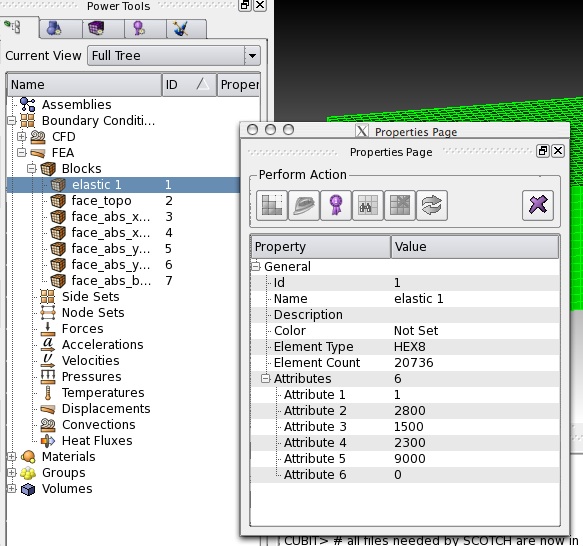

5. optionally, you could modify the material properties of the halfspace, by going to change the block properties

the following table applies for elastic material properties:

| Name | block name must start with “elastic” for elastic materials followed by a unique identifier material_id |

|---|---|

| Attribute 1 | Material ID |

| Attribute 2 | P-wave speed |

| Attribute 3 | S-wave speed |

| Attribute 4 | Density |

| Attribute 5 | Quality factor |

| Attribute 6 | Anisotropy flag |

Once you changed the properties, you will have to re-export the mesh. This can be done, using the script run_cubit2specfem3d.py:

use the (Play Journal File) button and open the file "run_cubit2specfem3d.py"

This should refresh the files in directory “MESH/”.

Setting up example folder for simulations

We will set up the example folder for simulation runs:

* databases directory:

create a directory in_out_files/DATABASES_MPI/ into which you will put the mesh partitions:

[]$ cd SPECFEM3D/examples/homogeneous_halfspace [homogeneous_halfspace]$ mkdir -p in_out_files/DATABASES_MPI

* parameter files:

make sure you have the parameter files in a local directory in_data_files/ for the example:

[homogeneous_halfspace]$ ls -1 in_data_files/ Par_file CMTSOLUTION STATIONS

these files should already be provided in the example folder.

* executables: compile the executables in the root directory:

[]$ cd SPECFEM3D/ [SPECFEM3D]$ make

in case the compilation was successful, it will create the executables xdecompose_mesh_SCOTCH, xgenerate_databases and xspecfem3D in the bin/ directory

and create a local directory bin/ to link the executables from the root directory:

[]$ cd SPECFEM3D/examples/homogeneous_halfspace [homogeneous_halfspace]$ mkdir -p bin [homogeneous_halfspace]$ cd bin/ [bin]$ ln -s ../../../bin/xdecompose_mesh_SCOTCH [bin]$ ln -s ../../../bin/xgenerate_databases [bin]$ ln -s ../../../bin/xspecfem3D

All these steps and the following decomposition, database generation and solver run are put in a process.sh bash script file in the example folder. You can simply run the script:

[homogeneous_halfspace]$ ./process.sh

to do the setup and following steps for you. Please modify and adapt the script to your needs.

Mesh partitioning

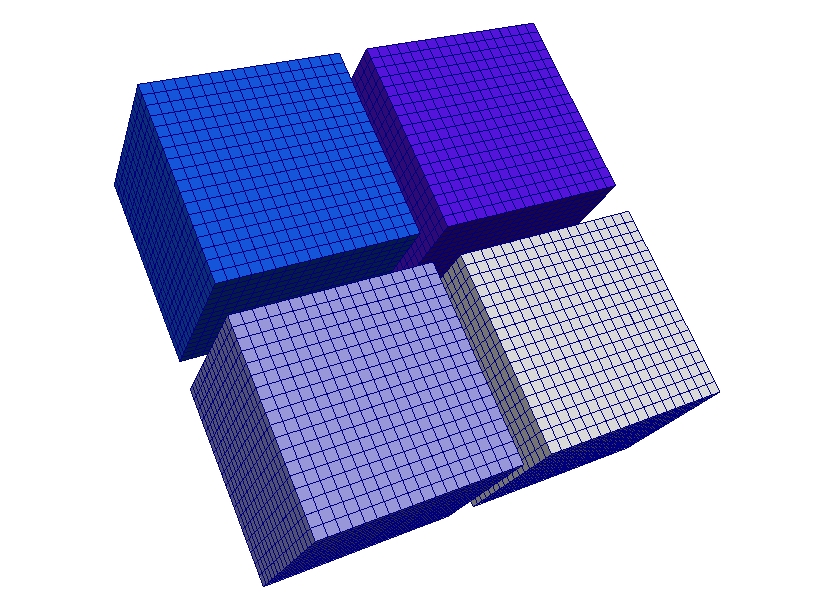

In this example, we will partition the mesh for 4 CPU cores.

run the mesh partitioner:

[homogeneous_halfspace]$ ./bin/xdecompose_mesh_SCOTCH 4 MESH/ in_out_files/DATABASES_MPI/

check that this created the mesh partitions:

[homogeneous_halfspace]$ ls -1 in_out_files/DATABASES_MPI/ proc000000_Database proc000001_Database proc000002_Database proc000003_Database

You are done.

Database generation

Next, you will need to create the mesh databases.

1. in case you can run parallel programs on your desktop (needs an MPI installation), you can run the executable like:

[homogeneous_halfspace]$ cd bin/ [bin]$ mpirun -np 4 ./xgenerate_databases

otherwise, you will need to modify and adapt one of the cluster scripts provided in the SPECFEM3D/utils/Cluster/ directory.

2. check the output file in_out_files/OUTPUT_FILES/output_mesher.txt to see if the databases were generated successfully.

The output file contains the suggested time step for your mesh:

Verification of simulation parameters ... Minimum period resolved = 2.115564 **Maximum suggested time step = 6.8863556E-02**

Forward simulation

To run a forward simulation, do the following:

1. make sure, you have the parameter files in the directory in_data_files/.

Most parameters in the Par_file should be set before running the database generation.

The following may be changed after running xgenerate_databases:

# forward or adjoint simulation SIMULATION_TYPE = 1 # 1 = forward, 2 = adjoint, 3 = both simultaneously NOISE_TOMOGRAPHY = 0 # 0 = earthquake simulation, 1/2/3 = three steps in noise simulation SAVE_FORWARD = .false. # time step parameters NSTEP = 1000 DT = 0.05 # absorbing boundary conditions for a regional simulation ABSORBING_CONDITIONS = .false. # save AVS or OpenDX movies MOVIE_SURFACE = .false. MOVIE_VOLUME = .false. NTSTEP_BETWEEN_FRAMES = 200 CREATE_SHAKEMAP = .false. SAVE_DISPLACEMENT = .false. USE_HIGHRES_FOR_MOVIES = .false. HDUR_MOVIE = 0.0 # interval at which we output time step info and max of norm of displacement NTSTEP_BETWEEN_OUTPUT_INFO = 500 # interval in time steps for writing of seismograms NTSTEP_BETWEEN_OUTPUT_SEISMOS = 10000 # interval in time steps for reading adjoint traces NTSTEP_BETWEEN_READ_ADJSRC = 0 # 0 = read the whole adjoint sources at the same time # print source time function PRINT_SOURCE_TIME_FUNCTION = .false.

2. in case you can run parallel programs on your desktop (needs an MPI installation), you can run the executable like:

[homogeneous_halfspace]$ cd bin/ [bin]$ mpirun -np 4 ./xspecfem3D

this example should take about 5 minutes to finish the simulation.

3. check the output file output_solver.txt in the output directory in_out_files/OUTPUT_FILES/ to see if the forward simulation was successfully finishing.

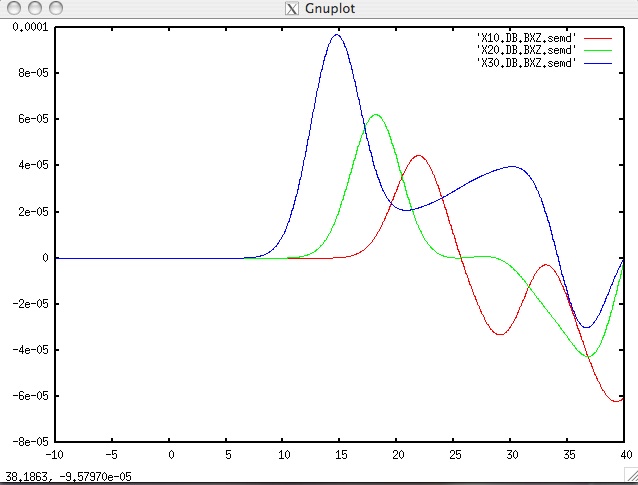

the seismograms will look like this, using gnu plot:

gnuplot> plot "X10.DB.BXZ.semd" w l,"X20.DB.BXZ.semd" w l,"X30.DB.BXZ.semd" w l

Tutorial 2: Waterlayered halfspace

The following instructions assume that you have installed SPECFEM3D and familiarized yourself with how you will run the package based on your computer configuration, as detailed in the SPECFEM3D User manual (Chapter 2 provides installation help). Additionally, we will make use of an external, hexahedral mesher CUBIT. Please make sure you have these packages installed on your system.

The example is distributed with the package under the examples/ directory. However, you might need to edit these example scripts slightly to launch them on your system.

Waterlayered halfspace

This is a step-by-step tutorial how to create a mesh for a layered halfspace with a water layer on top, export it into a SPECFEM3D file format and run the mesh partitioning and database generation.

Meshing

In the following, we will run a python script within CUBIT to create the needed mesh files for the partitioner.

1. change your working directory to the example folder:

<pre> []$ cd SPECFEM3D/examples/waterlayered_halfspace </pre>

2. start the graphical user interface (GUI) of “CUBIT”:http://cubit.sandia.gov:

<pre> [waterlayered_halfspace]$ claro </pre>

<p align="center"><a href="figures/cubit12.jpg/image_view"><img src="figures/cubit12.jpg" width=640 ></a></p>

3. run the python file:

<pre> use the (Play Journal File) button and open the file "waterlayer_mesh_boundary_fig8.py"</pre>

4. in case the script executed successfully, it should create you three volumes with a refined mesh for the top layer, a triplication layer and a coarser mesh layer at the bottom:

<p align="center"><a href="figures/cubit_waterlayered.jpg/image_view"><img src="figures/cubit_waterlayered.jpg" width=640 ></a></p>

check that the script created a new folder "MESH/" containing the files: <pre> [waterlayered_halfspace]$ ls -1 MESH/ absorbing_surface_file_bottom absorbing_surface_file_xmax absorbing_surface_file_xmin absorbing_surface_file_ymax absorbing_surface_file_ymin free_surface_file materials_file mesh_file nodes_coords_file nummaterial_velocity_file</pre>

you can also check if the export was successful by examining the output in the Command line window of CUBIT. The sensitive part should look like

<p align="center"><a href="figures/cubit_commandline_waterlayered.jpg/image_view"><img src="figures/cubit_commandline_waterlayered.jpg" width=400 ></a></p>

5. optionally, you could modify the material properties of the model,

either in CUBIT or in the newly created material file:

- changing the block properties in CUBIT

<p align="center"><a href="figures/cubit_properties_waterlayered.jpg/image_view"><img src="figures/cubit_properties_waterlayered.jpg" width=400 ></a></p>

the following table applies for **acoustic** material properties:

|------------------------------------------------------------------------------------------| | **Name** | block name must start with "acoustic" | | | for acoustic materials followed by a unique identifier ''material_id''| |------------------------------------------------------------------------------------------| | **Attribute 1** | Material ID | |------------------------------------------------------------------------------------------| | **Attribute 2** | P-wave speed | |------------------------------------------------------------------------------------------| | **Attribute 3** | S-wave speed is ignored, set to zero | |------------------------------------------------------------------------------------------| | **Attribute 4** | Density | |------------------------------------------------------------------------------------------|

the following table applies for **elastic** material properties:

|------------------------------------------------------------------------------------------| | **Name** | block name must start with "elastic" | | | for elastic materials followed by a unique identifier ''material_id'' | |------------------------------------------------------------------------------------------| | **Attribute 1** | Material ID | |------------------------------------------------------------------------------------------| | **Attribute 2** | P-wave speed | |------------------------------------------------------------------------------------------| | **Attribute 3** | S-wave speed | |------------------------------------------------------------------------------------------| | **Attribute 4** | Density | |------------------------------------------------------------------------------------------| | **Attribute 5** | Quality factor | |------------------------------------------------------------------------------------------| | **Attribute 6** | Anisotropy flag | |------------------------------------------------------------------------------------------|

Once you changed the properties, you will have to re-export the mesh. This can be done, using the script ''run_cubit2specfem3d.py'': <pre> use the (Play Journal File) button and open the file "run_cubit2specfem3d.py"</pre>

This should refresh the files in directory "MESH/".

- directly modifing the file

nummaterial_velocity_filein theMESH/directory:

<pre class=“file”> 1 1 1028.000000 1480.000000 0.000000 0.000000 0 2 2 3200.000000 7500.000000 4300.000000 9000.000000 0 2 3 3200.000000 7500.000000 4300.000000 9000.000000 0

</pre>

this file defines the material properties. the format is:

|---------------------------------------------------------------------------------------------------------------------------------------------------------------------------| | **Domain_id** | **Material_id** | **Density** | **P-wave speed** | **S-wave speed** | **Quality factor** | **Anisotropy_flag** | |---------------------------------------------------------------------------------------------------------------------------------------------------------------------------| | <code>1</code> = acoustic,<br> | unique material | density | wave speed in m/s | wave speed in m/s <br>| Quality factor,<br> | flag for anisotropy model,<br> | | <code>2</code> = elastic | identifier | in kg/m<sup>3</sup> | | (ignored for acoustic | 0 = no attenuation | 0 = no anisotropy | | | | | | materials) | | | |---------------------------------------------------------------------------------------------------------------------------------------------------------------------------|

<hr>

Setting up example folder for simulations

We will set up the example folder for simulation runs:

* databases directory:

create a directory ''in_out_files/DATABASES_MPI/'' into which you will put the mesh partitions: <pre> []$ cd SPECFEM3D/examples/waterlayered_halfspace [waterlayered_halfspace]$ mkdir -p in_out_files/DATABASES_MPI </pre>

* parameter files:

make sure you have the parameter files in a local directory ''in_data_files/'' for the example: <pre> [waterlayered_halfspace]$ ls -1 in_data_files/ Par_file CMTSOLUTION STATIONS </pre>

these files should already be provided in the example folder.

* executables:

compile the executables in the root directory: <pre> []$ cd SPECFEM3D/ [SPECFEM3D]$ make </pre>

in case the compilation was successful, it will create the executables ''xdecompose_mesh_SCOTCH'', ''xgenerate_databases'' and ''xspecfem3D'' in the ''bin/'' directory and create a local directory ''bin/'' to link the executables from the root directory: <pre> []$ cd SPECFEM3D/examples/waterlayered_halfspace [waterlayered_halfspace]$ mkdir -p bin [waterlayered_halfspace]$ cd bin/ [bin]$ ln -s ../../../bin/xdecompose_mesh_SCOTCH [bin]$ ln -s ../../../bin/xgenerate_databases [bin]$ ln -s ../../../bin/xspecfem3D </pre>

All these steps and the following decomposition, database generation and solver run are put in a process.sh bash script file in the example folder. You can simply run the script:

<pre> [waterlayered_halfspace]$ ./process.sh </pre>

to do the setup and following steps for you. Please modify and adapt the script to your needs.

Mesh partitioning

In this example, we will partition the mesh for 4 CPU cores.

run the mesh partitioner:

<pre> [waterlayered_halfspace]$ ./bin/xdecompose_mesh_SCOTCH 4 MESH/ in_out_files/DATABASES_MPI/ </pre>

check that this created the mesh partitions:

<pre> [waterlayered_halfspace]$ ls -1 in_out_files/DATABASES_MPI/ proc000000_Database proc000001_Database proc000002_Database proc000003_Database </pre>

<p align=“center”><a href=“figures/scotch_partitions_waterlayered.jpg/image_view”><img src=“figures/scotch_partitions_waterlayered.jpg” width=400 ></a></p>

You are done.

<hr>

Database generation

Next, you will need to create the mesh databases.

1. in case you can run parallel programs on your desktop (needs an MPI installation), you can run the executable like:

<pre> [waterlayered_halfspace]$ cd bin/ [bin]$ mpirun -np 4 ./xgenerate_databases </pre>

otherwise, you will need to modify and adapt one of the cluster scripts provided in the ''SPECFEM3D/utils/Cluster/'' directory.

2. check the output file in_out_files/OUTPUT_FILES/output_mesher.txt to see if the databases were generated successfully.

The output file contains the suggested time step for your mesh: <pre class="file"> Verification of simulation parameters ... Minimum period resolved = 1.632425 **Maximum suggested time step = 5.1801954E-03** </pre>

<hr>

Forward simulation

To run a forward simulation, do the following:

1. make sure, you have the parameter files in the directory in_data_files/.

Most parameters in the ''Par_file'' should be set before running the database generation. The following may be changed after running ''xgenerate_databases'': <pre class="file"> # forward or adjoint simulation SIMULATION_TYPE = 1 # 1 = forward, 2 = adjoint, 3 = both simultaneously NOISE_TOMOGRAPHY = 0 # 0 = earthquake simulation, 1/2/3 = three steps in noise simulation SAVE_FORWARD = .false.

# time step parameters NSTEP = 4500 DT = 0.005

# absorbing boundary conditions for a regional simulation ABSORBING_CONDITIONS = .true.

# save AVS or OpenDX movies MOVIE_SURFACE = .false. MOVIE_VOLUME = .false. NTSTEP_BETWEEN_FRAMES = 200 CREATE_SHAKEMAP = .false. SAVE_DISPLACEMENT = .false. USE_HIGHRES_FOR_MOVIES = .false. HDUR_MOVIE = 0.0

# interval at which we output time step info and max of norm of displacement NTSTEP_BETWEEN_OUTPUT_INFO = 500

# interval in time steps for writing of seismograms NTSTEP_BETWEEN_OUTPUT_SEISMOS = 10000

# interval in time steps for reading adjoint traces NTSTEP_BETWEEN_READ_ADJSRC = 0 # 0 = read the whole adjoint sources at the same time

# print source time function PRINT_SOURCE_TIME_FUNCTION = .false. </pre>

2. in case you can run parallel programs on your desktop (needs an MPI installation), you can run the executable like:

<pre> [waterlayered_halfspace]$ cd bin/ [bin]$ mpirun -np 4 ./xspecfem3D </pre>

note, this example should take about 1 hour 45 minutes to finish the simulation.

3. check the output file output_solver.txt in the output directory in_out_files/OUTPUT_FILES/

to see if the forward simulation was successfully finishing.

the seismograms will look like this, using gnuplot: <pre> gnuplot> plot "X10.DB.BXZ.semd" w l,"X20.DB.BXZ.semd" w l,"X30.DB.BXZ.semd" w l </pre>

<p align="center"><a href="figures/waterlayered_seismograms.jpg/image_view"><img src="figures/waterlayered_seismograms.jpg" width=500 ></a></p>